Innovating the field of metal manufacturing: Industrial M300 Laser SLM 3D Metal Printer is stunning! titanium weld

At today’s Global Technology Top, an industry titan launched its most current masterpiece – the Industrial M300 Laser SLM 3D Metal Printer, noting an additional development in 3D printing innovation in precision manufacturing This advanced steel 3D printer, with its unmatched printing precision and production effectiveness, is leading several essential areas, such as aerospace, vehicle manufacturing, and clinical equipment, right into a brand-new age of intelligent production.

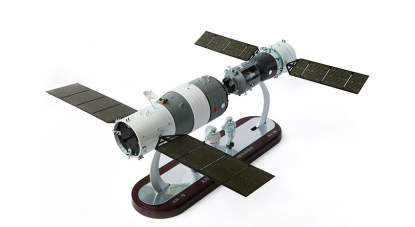

(Industrial M300)

Technological technology, reshaping the future of production.

The Industrial M300 takes on sophisticated Discerning Laser Melting (SLM) innovation, which exactly thaws steel powder layers with high-energy laser beam of lights, constructing complicated and high-strength steel parts layer by layer. Compared to traditional production methods, SLM innovation not only considerably shortens the product growth cycle however likewise achieves a qualitative jump in product application and design adaptability. The launch of this printer is a complete subversion of the existing production version, turning previously challenging style ideas right into fact.

Outstanding performance, specifying new industry requirements

The greatest highlight of this printer is its incredibly huge printing volume of up to 600 x 600 x 600 mm, which is exceptionally unusual among similar items and supplies the possibility for incorporated printing of large intricate structural components. Paired with a 12-laser concurrent os, not only does it boost the printing speed to an unmatched 1000ccm/h, yet it also guarantees the ultimate accuracy of every information, with mistakes regulated at the micrometer degree. On top of that, the introduction of bidirectional repainting and double dive rate works even more maximizes printing efficiency and surface area top quality, accomplishing real high performance and high-precision similarity.

Environmental management and power conservation, replying to the call for green manufacturing

The firm is devoted to lasting advancement, and the Industrial M300 integrates environmental protection ideas from the start of its style. The shut cycle powder monitoring system embraced successfully lowers the loss of metal powder and ecological pollution, achieving effective recycling of materials. At the same time, progressed energy monitoring systems make sure energy intake optimization throughout the printing process, contributing to the realization of environment-friendly production.

Widely appropriate, opening up diversified market potential customers

With the launch of the Industrial M300, its application in the aerospace area is particularly popular, as it can directly print light-weight architectural components, considerably minimizing aircraft weight and boosting gas performance. In the auto manufacturing industry, it is utilized to rapidly create high-performance engine parts and digital drive elements, increasing the research and development process of new energy lorries. In the clinical field, the on-demand printing of individualized medical tools and implants brings even more exact treatment plans to people.

(Industrial M300 for printing aerospace lightweight structural components)

The chief executive officer of the company stressed at journalism meeting that “the Industrial M300 is not only an upgrade in hardware but also a profound understanding and design for the future of manufacturing.” With the launch of this front runner 3D metal printer, the global market is experiencing a magnificent improvement from principle to product and a brand-new production era with digitalization and intelligence as its core functions.

Concerning Kmpass

Kmpass is committed to technology development, applications of nanotechnology and new material industries, with professional experiencein the nano-technology research and development and the application of materials.especially for 3d printing powder, 3d printing metal powder, 3d printing powder supplier, 3d printing for titanium powder. As a leading nano-technology development and product applications additive manufacturer, Kmpass dominates the markets. If you need high quality titanium weld, please feel free to contact us.

Inquiry us